Abstract: As a core component of the solid control industry, the slurry separation system plays a pivotal role in various fields, including oil drilling, mining, and tunnel tunnelling. This paper delves into the technical principles, system composition, application areas, and development trends of the slurry separation system, while also exploring its future trajectory.

Keywords: solid control;slurry separation; shale shaker; centrifuge; environmental protection

I. Introduction

With the relentless advancement of industrial production, the demand for resources has surged, leading to the expansion of projects such as drilling and mining. Consequently, the volume of mud generated has escalated significantly. Mud, which contains a substantial quantity of solid particles, may also harbour harmful substances such as oil and chemical additives. If discharged untreated, it poses a severe threat to the environment. The advent of the slurry separation system has addressed this issue by effectively segregating solid particles from the liquid in the mud, thereby facilitating the purification and recycling of the mud. This system is instrumental in environmental conservation and resource efficiency.

II. Technical Principles of the Slurry Separation System

The slurry separation system predominantly employs physical methods to separate solid particles from the liquid in the mud, based on the differences in density and particle size of various substances. Common separation techniques include:

Screening Separation: Utilises equipment such as vibrating screens and drum screens to separate solid particles of varying sizes through the aperture of the screen.

Centrifugal Separation: Leverages the centrifugal force generated by the high-speed rotation of a centrifuge to separate solid particles and liquids of different densities.

Gravity Sedimentation: Employs gravity to induce the natural settling of denser solid particles, thereby achieving solid-liquid separation.

Filtration Separation: Uses filter media (e.g., filter cloth, filter paper) to intercept and separate solid particles from the liquid.

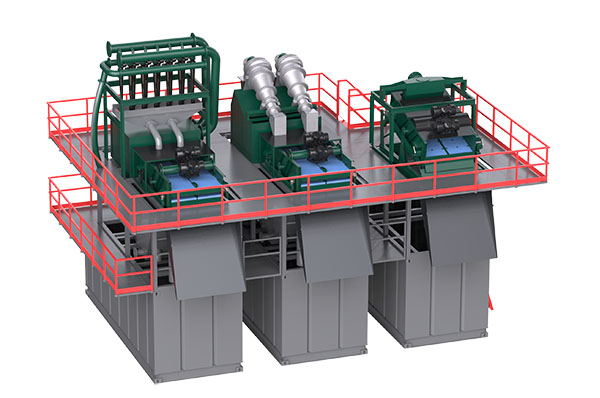

III. Composition of the slurry Separation System

A comprehensive mud-water separation system typically comprises the following components:

Shale Shaker: Removes large solid particles from the mud, serving as the initial stage of mud-water separation.

Desander: Eliminates sand from the mud, enhancing its cleanliness.

Mud Remover: Extracts fine particles from the mud, further purifying it.

Centrifuge: Removes minute and colloidal particles from the mud, achieving a deeper level of purification.

Mud Tank: Stores and processes the separated mud.

Conveying Equipment: Transports the mud to various processing stages.

IV. Application Areas of the Slurry Separation System

The mud-water separation system finds extensive application in the following domains:

Oil Drilling: Treats mud generated during drilling operations, recovers drilling fluid, and mitigates environmental pollution.

Mining: Processes mud produced during mining activities, recovers valuable minerals, and reduces tailings discharge.

Tunnel Tunnelling: Manages mud generated during tunnelling, enhances tunnelling efficiency, and minimises environmental impact.

Municipal Engineering: Addresses mud from river dredging and pipe cleaning projects, improving urban environments.

Environmental Protection: Treats industrial wastewater and domestic sewage, purifies water quality, and safeguards the environment.

V. Development Trends of the Mud-Water Separation System

With increasingly stringent environmental regulations and continuous technological advancements, the mud-water separation system is evolving in the following directions:

High Efficiency: Enhances the efficiency of mud-water separation, reduces processing time, and lowers operational costs.

Intelligence: Incorporates automated control technologies to enable intelligent operation of the system.

Environmental Sustainability: Utilises eco-friendly materials and processes to minimise secondary pollution during mud-water separation.

Integration: Integrates with other environmental protection equipment to form comprehensive solutions.

VI. Conclusion

As an integral part of the solid control industry, the mud-water separation system plays an increasingly vital role in environmental protection and resource utilisation. With ongoing technological progress and the expansion of its application fields, the mud-water separation system is poised for a promising future, offering broader prospects for development.