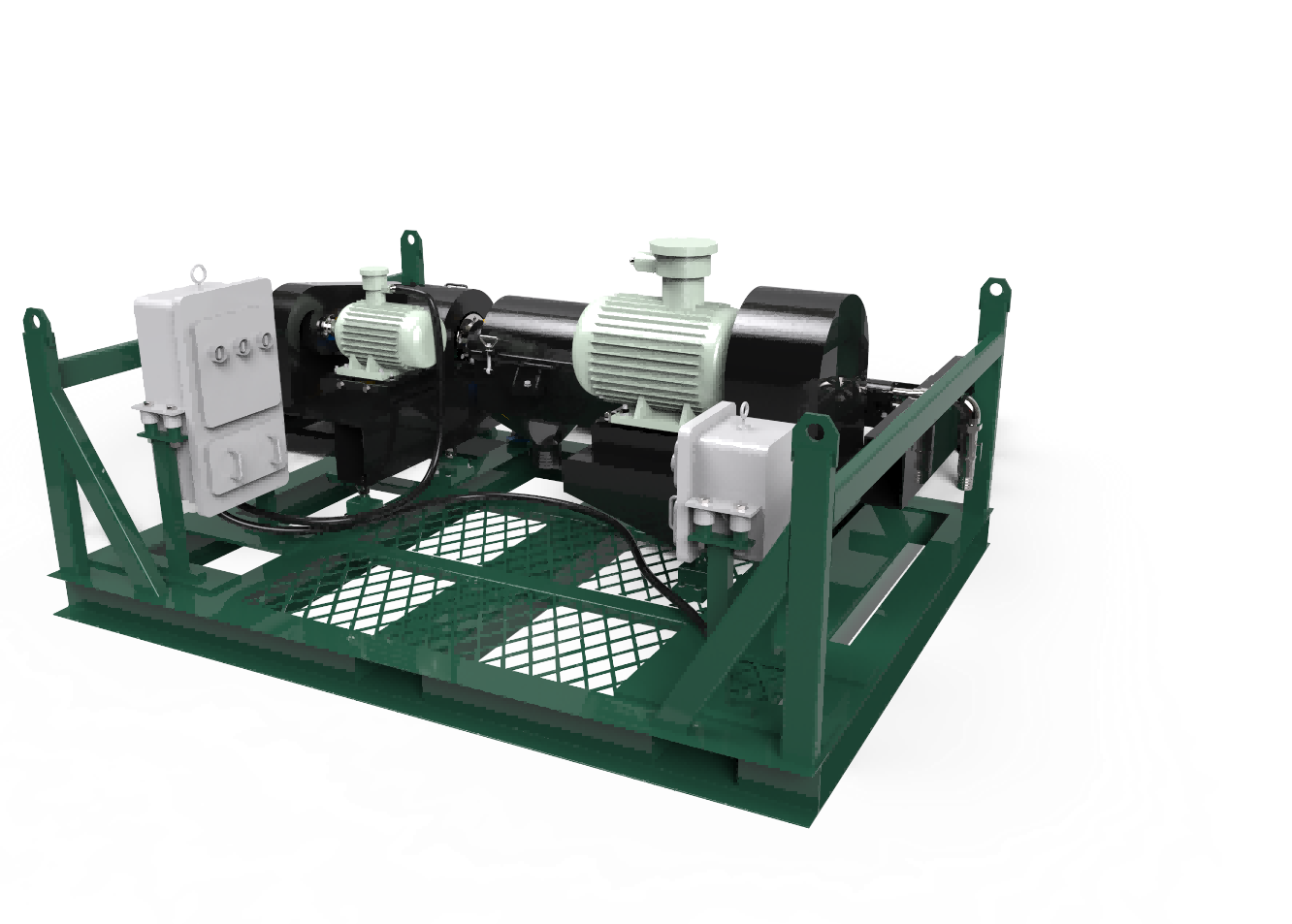

The Black Rhino Centrifuge represents a cutting-edge solution for separation processes, built with robust components and advanced technology to ensure maximum performance, efficiency, and longevity.

It is specifically designed for industries that require reliable and durable equipment under heavy-duty operational conditions. The centrifuge integrates several key features to protect the motor, enhance performance, and improve maintenance efficiency. Below, we provide an in-depth look at the centrifuge's main components:

The hydraulic coupler in the Black Rhino Centrifuge acts as a flexible transmission device that connects to the main motor shaft. This design ensures smooth startup operations by allowing the motor to start under an almost unloaded condition, significantly reducing the initial starting current. As a result, the motor experiences less strain during startup, contributing to a longer lifespan.

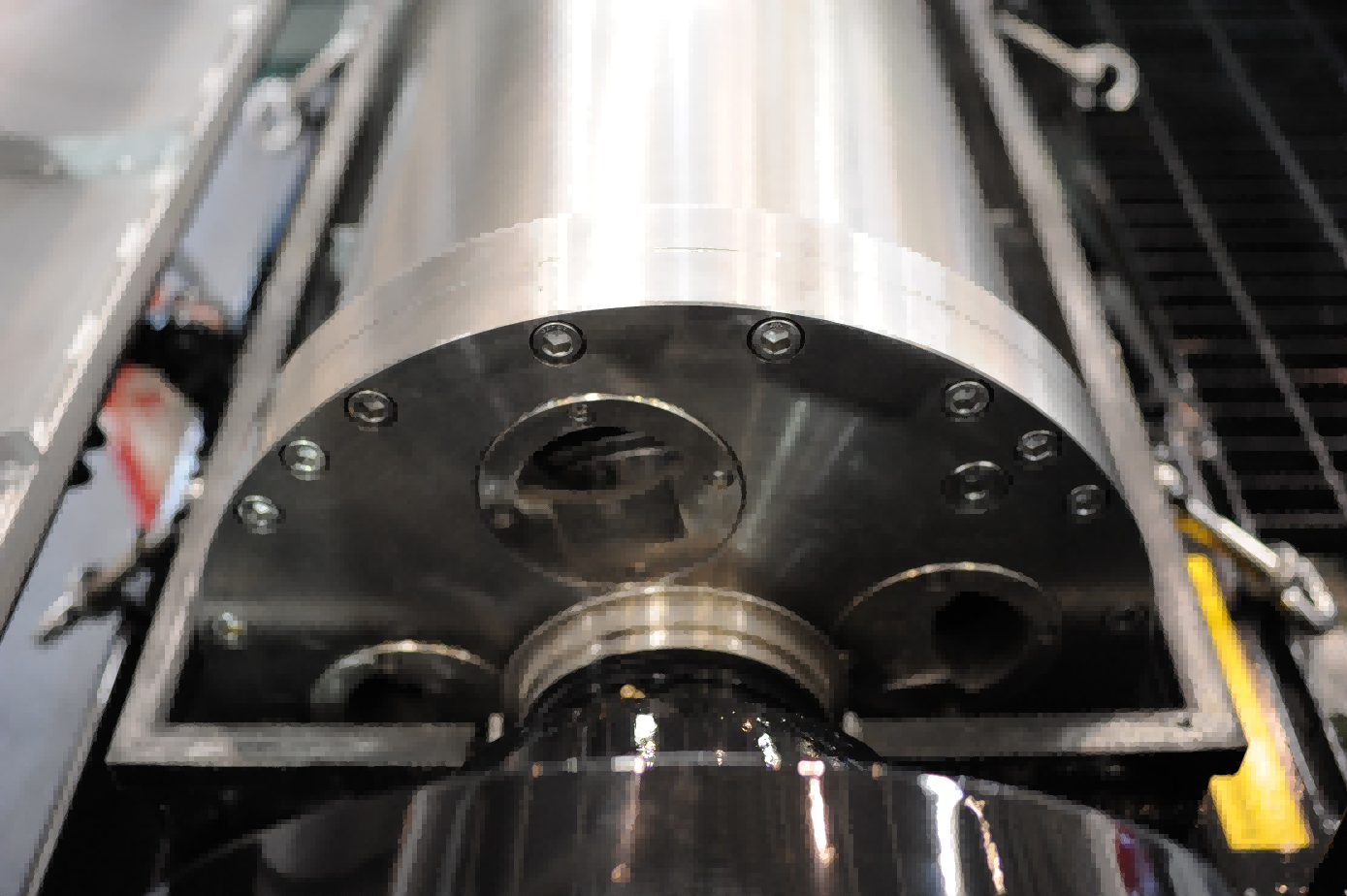

The drum is a critical component of the centrifuge, primarily constructed from high-quality stainless steel materials such as 304, 321, 316L, and 316 grades. This choice of materials ensures superior resistance to corrosion, making the drum highly durable in challenging operational environments.

Inside the drum, a spiral propeller is mounted to propel the solid material. The blades of the propeller are coated with wear-resistant tungsten carbide or fitted with hard alloy tips, which significantly extend the service life of the propeller, even under continuous operation.

At the small end of the drum, the dreg outlet is constructed from highly wear-resistant materials such as tungsten or cobalt to ensure it can withstand the high-impact and abrasive conditions typical in centrifuge operations. Meanwhile, the large end of the drum is equipped with replaceable, wear-resistant liquid level rings. These rings allow for easy adjustment of the liquid level depth, ensuring optimal separation efficiency.

For even greater flexibility and control, the centrifuge can also be equipped with an explosion-proof variable frequency control cabinet, which allows for precise adjustments to the centrifuge's operational speed, further enhancing its efficiency and adaptability to different processing conditions.

The differential is a vital component that controls the speed ratio between the motor and the drum. The gear-reducing structure connects the differential housing to the drum. The input shaft connects to the auxiliary motor via a belt pulley, and the rotational speed output from both the motor and auxiliary motor is transmitted to the spiral propeller via a spline shaft.

This differential structure is designed to provide high torque and ensure a constant differential speed, critical for maintaining consistent performance under varying load conditions. The differential utilizes one of three advanced transmission structures: planetary gear, cycloidal pin gear, or hydraulic, each designed to optimize the centrifuge's operation based on the specific needs of the application.

The Black Rhino Centrifuge is an advanced and highly durable separation solution built to withstand the toughest operational conditions. Its cutting-edge components, including the hydraulic coupler, stainless steel drum, explosion-proof control system, and high-torque differential, work together to ensure efficient and reliable operation. With built-in protection mechanisms and long-lasting materials, the Black Rhino Centrifuge offers exceptional performance and longevity, making it the ideal choice for industries requiring high-performance separation equipment.