Description of mud-water separation scheme of shield As an advanced excavation construction technology, shield tunneling plays an important role in tunnel engineering with its fully mechanized characteristics. In this method, the shield machine is us...

Description of mud-water separation scheme of shield

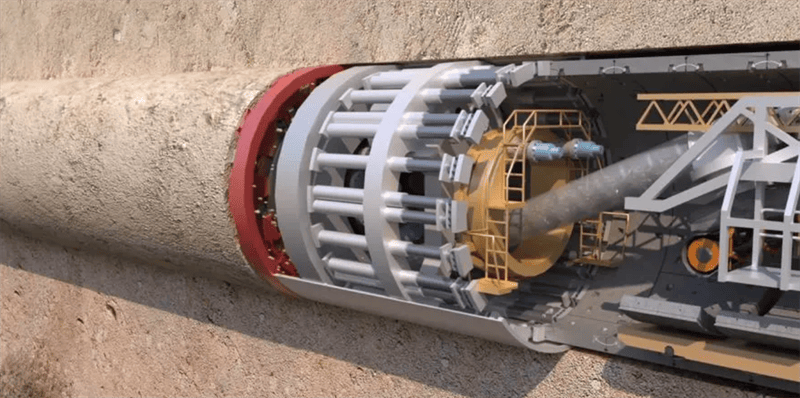

As an advanced excavation construction technology, shield tunneling plays an important role in tunnel engineering with its fully mechanized characteristics. In this method, the shield machine is used to advance underground, and the surrounding rock is supported by the shield shell and prefabricated segments, which can effectively prevent the tunnel collapse. During the construction process, the cutting device excavates the soil in front, the excavating machine transports the muck to the surface, and at the same time, the concrete segments are pushed and assembled by hydraulic jacks to form the complete tunnel structure.

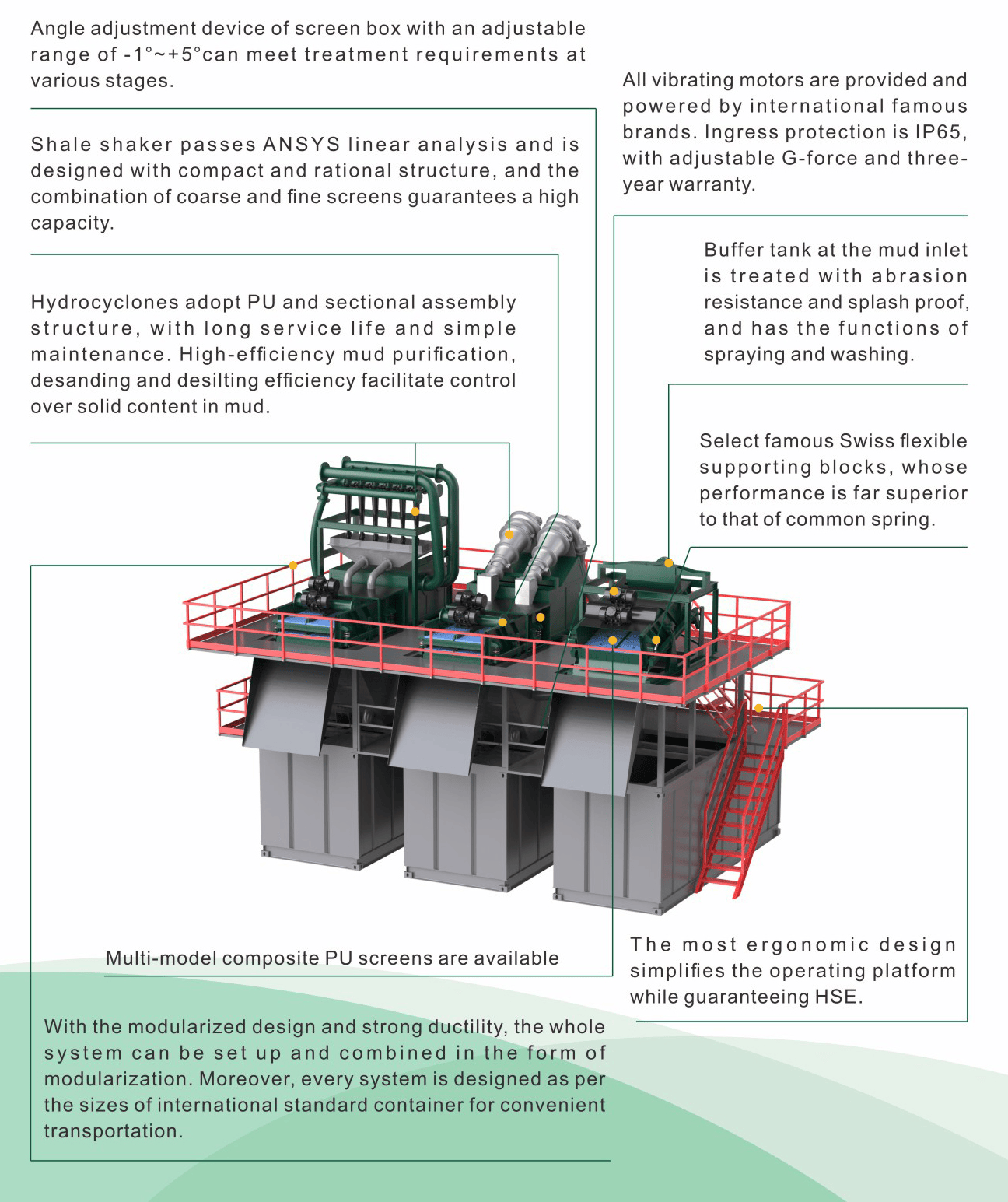

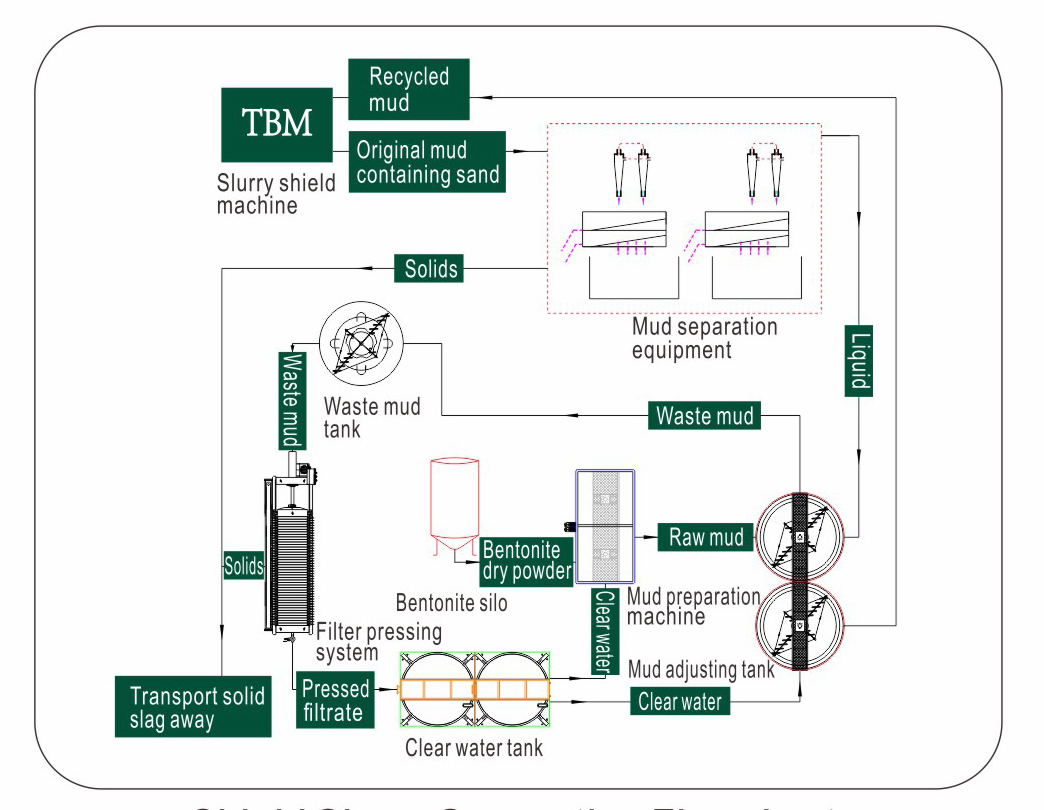

In shield construction, the Black Rhino mud-water separation system has become the industry benchmark for its outstanding performance, and the system consists of four core components: vibrating screen, sand cyclone, sand pump and cone tank. Among them, the vibrating screen adopts a double-layer screen design, the thick screen can effectively remove the large particles of slag in the mud, and the sand cyclone and the fine number of screens work together to remove more fine sand particles. The system adopts the mud closed-circuit purification process, which not only realizes the lower water content of slag, but also significantly reduces the impact of construction on the environment. In addition, the system is made of anti-corrosion and wear-resistant materials to ensure long-term stable operation of the equipment under harsh conditions.

Slurry water separation process of shield

The advantages of Black Rhino's mud-water separation system

● Modular design, in line with container size, foldable operating platform makes the equipment compact, adapt to different site needs.

● Scientific process design, by adjusting the parameters of the vibrating screen (exciting force, inclination Angle, screen size), quickly adapt to various construction conditions.

● The use of advanced wear-resistant materials, especially composite wear-resistant pipes, significantly extend the life of the equipment.

● The process can be customized according to the characteristics of the material, and the processing capacity can reach 50-500 cubic meters/hour.

● Suitable for a variety of power systems, optional generator set, suitable for remote or unstable power areas.

● Support skid mounted or vehicle-mounted mobile design to meet the needs of different construction scenarios.

The Black Rhino mud-water separation system not only improves the efficiency of shield construction, but also provides strong technical support for modern tunnel construction through its environmentally friendly design and reliable performance. Its modular design and flexible configuration make it able to adapt to various complex geological conditions and construction environment, and become an indispensable important equipment in shield construction.