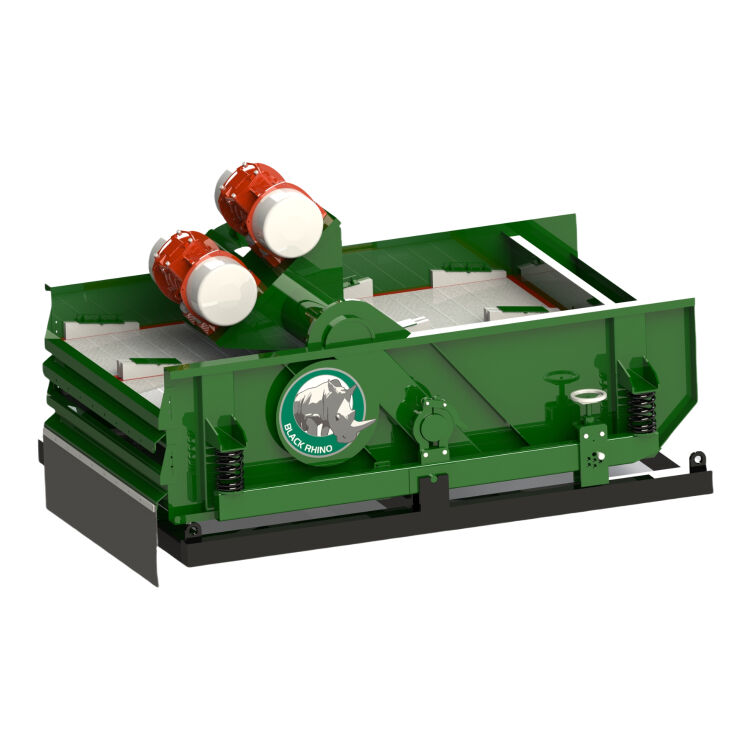

LS608 series shale shaker is a linear vibrating machine with a double-layer frame and two vibrating motors. Motors are mounted on the screen frame with support beams, applying G-force directly to the screen panels. The vibration isolation system protects the base frame. Slurry is fed through a feed box for pre-screening, separating larger particles. This improves slurry quality for hydro-cyclone separation, enhancing pile foundation hole formation rates and reducing costs.

Product Description

The LS608 series shale shaker is a linear vibrating machine equipped with a double-layer frame and two vibrating motors, capable of efficiently separating cuttings particles. In the LS608 series shale shaker, the vibrating motors are securely mounted to the screen frame using high-strength support beams and positioned on the screen bed. This method of positioning the vibrating motors allows the excitation force (G-force) to be directly applied to the screen panels. The vibration isolation system ensures that the base frame remains unaffected by the vibrations of the screen frame. Slurry feed is directed into the LS608 series shale shaker through a feed box, where larger particles are initially separated from the slurry pool. This pre-screening process prepares the slurry for the subsequent hydro-cyclone separation, ensuring slurry quality, improving pile foundation hole formation rates, and reducing bentonite usage and slurry preparation costs.

Model Parameters

Model No. |

LS608 Shale Shaker |

Line of mode |

Linear |

Motor type |

Short motor |

Power(kW)/(hp) |

1.72 kW×2 |

Vibration Strength(G-Force) |

6.5~7.0G adjustable |

Screen total area(㎡)/(ft2) |

4.92㎡ |

Screen Angle adjustment range( °) |

-1°~5° |

Processing capacity(m3/h)/(GPM) |

25T~85T/h |

Screen Type |

Plate Screen |

Screen size(mm)/(in) |

1000×615 |

Number of screens |

4 above/ 4 below |

Noise(dB) |

<85 |

Dimensions L*W*H(mm)/(in) |

2305×1722×1674 |

Weight(kg)/(lbs) |

1550 |

Competitive Advantage

● Utilizes advanced linear vibration principles and high-open-area screens to achieve efficient solid-liquid separation with high processing capacity.

● Key components are made of high-strength, wear-resistant materials, ensuring durability and a long service life.

● Features a modular design with a simple structure, enabling convenient and quick maintenance.

● Incorporates advanced vibration damping and noise reduction technology, ensuring smooth operation, low noise, and energy efficiency.

● Allows flexible adjustment of the number of screen layers, mesh sizes, and vibration parameters based on different material characteristics and process requirements, meeting diverse needs.

Applications

The BLACK RHINO LS608 shale shaker is a critical equipment for slurry screening and treatment, capable of precisely controlling the screening particle size to ensure stable processing results and meet the diverse particle size requirements of different customers. Its application fields mainly include the following aspects:

● Mining Screening

● Construction and Bridge Pile Foundation Engineering

● Underground Tunnel Shield Tunneling and Trenchless Engineering Construction

● Environmental Sludge Treatment

● River Dredging